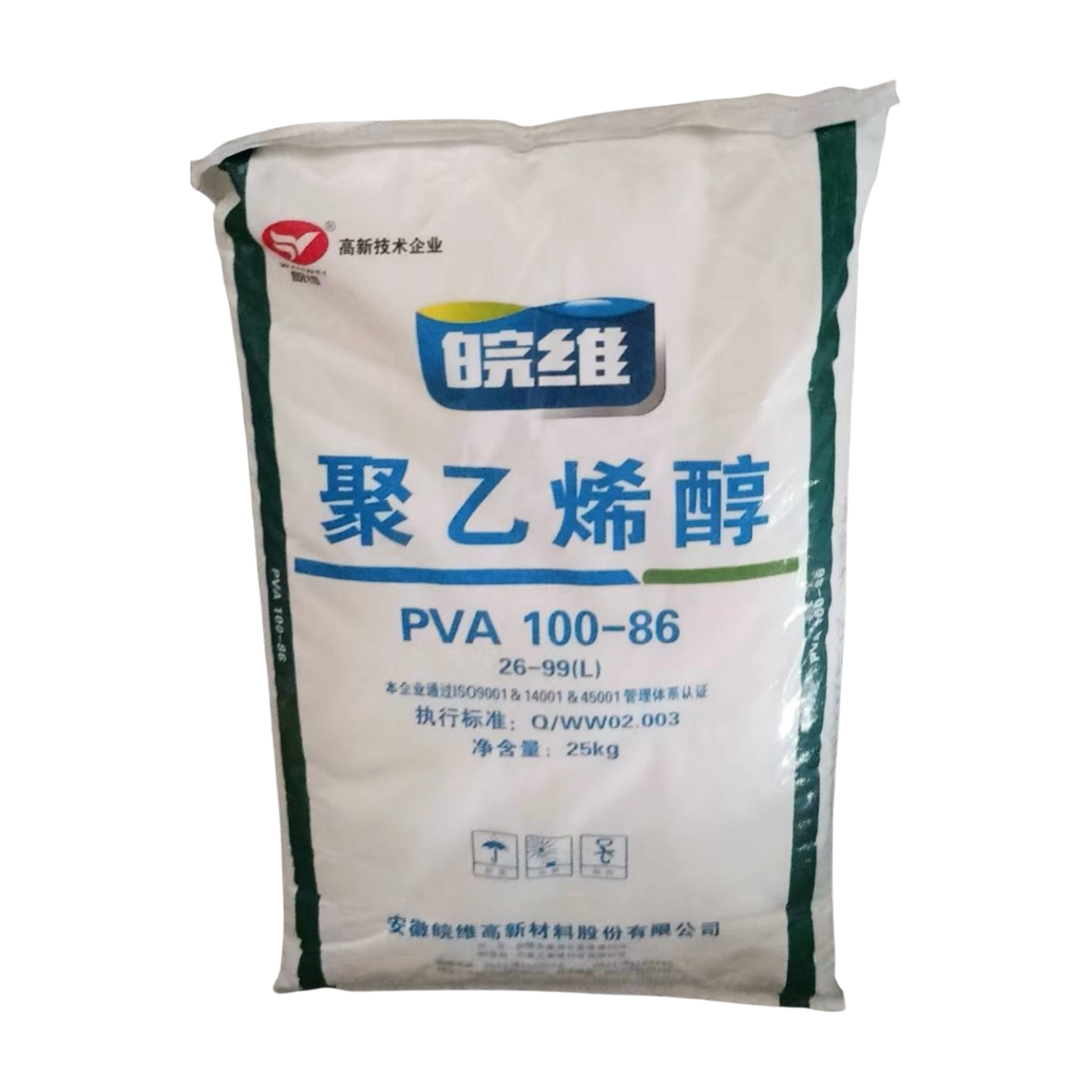

PVA and VAE are used both in coating applications, but what should one think about the particular functionalities of both substances? PVA, a synthetic polymer, is known for its high level of adhesion and good film clarity which allows it to be applied where appearance and flexibility are important. On the other hand, VAE emulsions have better water and weather proofing qualities making them ideal for outdoor use. Knowing these qualities enables clients to select the right emulsion depending on the demand of the application, ensuring maximum benefits and performance in coating endeavours at the required costs.