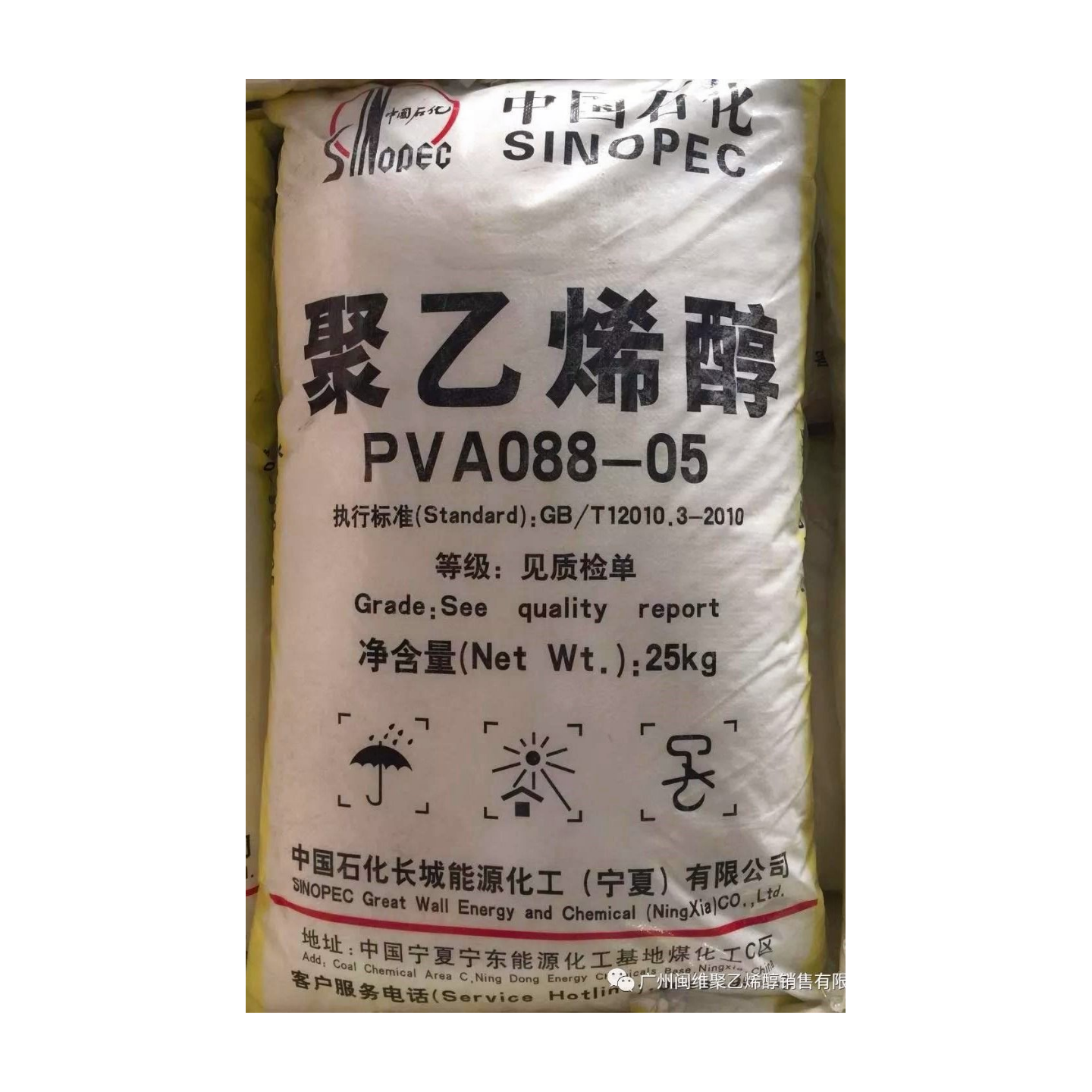

Polyvinyl Alcohol (PVA) is a copious synthetic polymer with exceptional film forming emulsifying and adhesive capabilities among other properties. It is worth noting that the major differences between the types of PVA are the molecular weight and the degree of hydrolysis which determine solubility, viscosity, and general applicability in the industries. For example, strong molecular weight PVA works best in applications needing strong bond whereas the weak molecular weight variants are used in coatings and films. These differences are particularly important for the manufacturers that want to maximize the performance of their formulations to achieve their desired product performance.