Biomass PVA

Description

Overview

Biomass Polyvinyl alcohol (PVA) is a non-toxic, odorless and easily degradable water-soluble polymer made from vinyl acetate by polymerization and alcoholysis. PVA aqueous solution has good film-forming, adhesion, emulsification. The formed film has excellent adhesion, solvent resistance, friction resistance and oxygen barrier properties, and has both hydrophilic and hydrophobic functional groups, so it has interfacial activity, and can be used as a protective colloid during polymer emulsification and suspension polymerization.

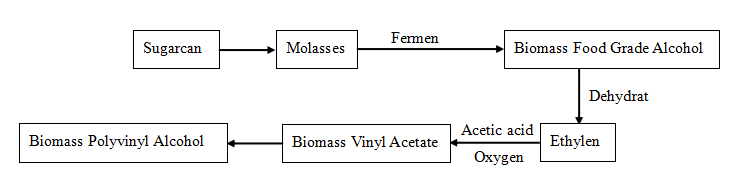

Technological process

Product quality index

|

Specification |

Item |

||||||||

|

Company standard |

Corresponding National Standards |

Degree of Alcoholysis/(mol/mol)% |

Average Degree of Polymerization |

Viscosity /mPa.s |

Volatile /%≤ |

Sodium Acetate /%≤ |

Ash /%≤ |

pH |

Purity /%≥ |

|

17-99(H) |

100-27H |

99.0-100.0 |

1600-1800 |

20.0-26.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

|

19-99(H) |

100-31H |

99.0-100.0 |

1800-2000 |

26.0-34.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

|

20-99(H) |

100-37H |

99.0-100.0 |

2000-2300 |

34.0-42.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

|

23-99(H) |

100-50H |

99.0-100.0 |

2300-2600 |

42.0-55.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

|

24-99(H) |

100-60H |

99.0-100.0 |

2600-2900 |

55.0-65.0 |

6.5 |

6.5 |

2.5 |

7-10 |

86.5 |

Application

Used in the production of synthetic fibers, plastics, adhesives, coatings, PVA packaging film, medical equipment and supplies, new building materials and other products.