Lately, there has been an increased focus on biodegradable products, particularly due to the recent changes in attitudes towards sustainable practices. One of the major materials that are sparking this revolution is Polyvinyl Alcohol (PVA). This article discusses the importance of PVA with respect to the production of biodegradable materials, PVA’s properties, uses, and future prospects within this important market.

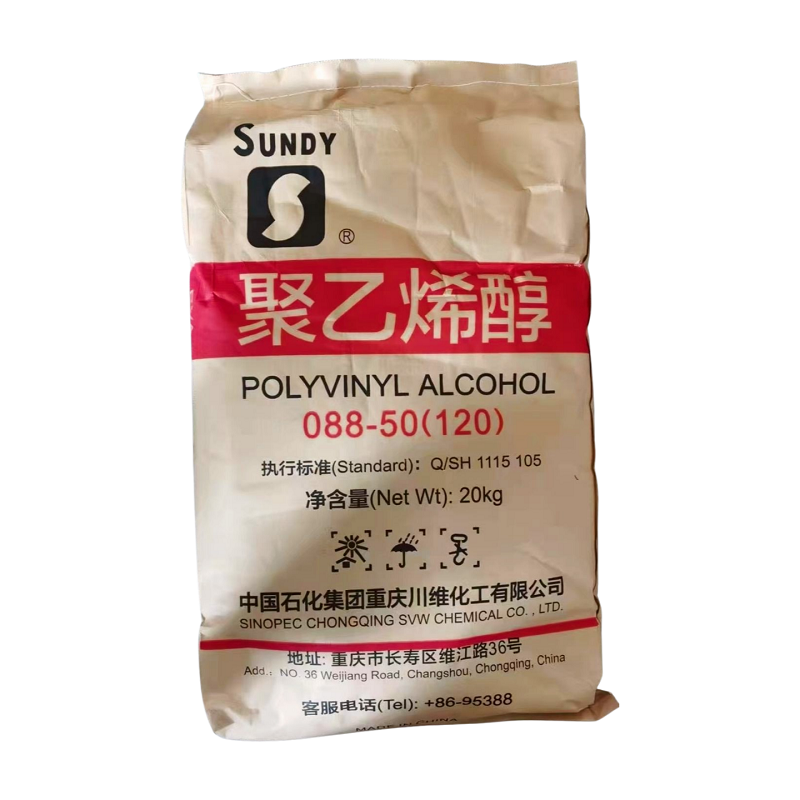

PVA is a synthetic polymer that is water-soluble and biodegradable. As a result of these advantageous properties, PVA can be used in various applications, especially in the packaging industry. With the heightening concern over environmental issues, the demand for biodegradable packaging alternatives has reached unprecedented levels. PVA promises a better solution than plastics, which are very harmful to the environment. With the introduction of PVA, manufacturers will design packs that protect items and are biodegradable thereby cutting down on the amount of material that ends up in landfills.

Apply PVA polymers to a larger scope such as Non-packaging applications are also possible. It finds applications in textiles, adhesives, and further in the medical industry for drug delivery systems. In the textile industry, PVA can be exploited to create biodegradable fibers which hold the structure of the fabric but gets decomposed after use. In adhesives, polyvinyl alcohol based adhesive glues possesses strong bonding power and does not use conventional environmental damaging based glues. The versatility of PVA makes it a valuable material for different industries willing to be environmentally friendly.

Another important positive effect of PVA is that it is compatible with various other biodegradable composites. It was found that if PVA is combined with various biopolymer concentrations the properties of the biobased product could be further enhanced. Such manner may result in better mechanical properties, enhanced barrier features and more complete degradation functionalities. As a result, manufacturers are looking into new formulations that utilize PVA in the way it was designed, allowing for more efficient biodegradable solutions.

There are several upsides of utilizing PVA in the manufacture of biodegradable products, but there are still a number of drawbacks. One downside would include that PVA is made in a manufacturing process that uses a lot of energy, and the availability of sourcing environmentally friendly materials to make PVA could be a concern. Nevertheless, there are still ongoing research and development programs that seek to solve these problems. Companies are now also focusing on better production alternatives and using renewable resources to manufacture PVA which will increase its desire in the market.

When looking to the future, the developers of biodegradable products lying in wait for inspiration from PVA may feel optimistic. With the rising global issues pertaining to plastic pollution and consumers actively seeking for environmentally friendly products, it can be anticipated that the demand for biodegradable materials will increase vastly. Biodegradable product manufacturers who put emphasis on the incorporation of PVA in their products, are expected to be at the forefront of this transformation. Besides, PVA promises to greatly disrupt a number of industries as technology advances and there is increased awareness on sustainability.

In conclusion, PVA assists in the production of bio-degradable materials and is a good substitute for regular plastics. PVA is very functional, can be used with other prospecting materials, and has advances. As PVA and other materials will be sustainable PVA is bound to be used more as the world seeks to reduce its ecological footprint.’