Wie PVA zur Verbesserung der Wasserbeständigkeit in Produkten beiträgt

Einführung in Polyvinylalkohol (PVA)

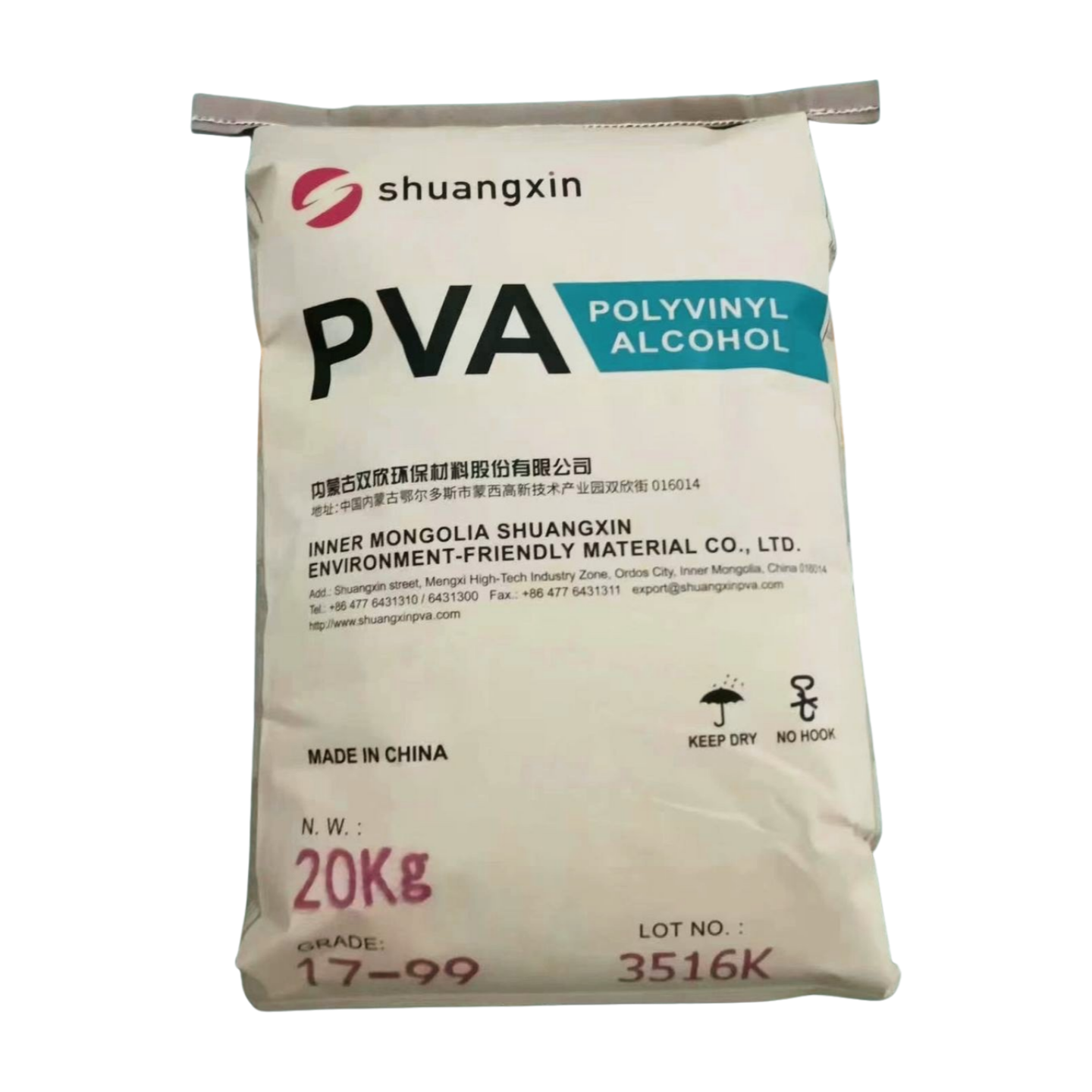

Was ist PVA?

Polyvinylalkohol (PVA) ist ein synthetisches Polymer, das hohe Zugfestigkeit, Flexibilität und hervorragende Filmformungseigenschaften aufweist. Seine einzigartige chemische Struktur ermöglicht es, in Wasser zu lösen, was es zu einem vielseitigen Material in verschiedenen Branchen macht. PVA ist biologisch abbaubar, was in der heutigen umweltbewussten Landschaft ein großer Vorteil ist.

Eigenschaften von PVA

Die Eigenschaften von PVA machen es äußerst geeignet für verschiedene Anwendungen. Es ist ungiftig, hat eine hohe Sauerstoffdurchlässigkeit und kann starke Filme bilden. Allerdings kann seine Wasserlöslichkeit ein zweischneidiges Schwert sein; während sie PVA leicht verarbeitbar macht, macht sie es auch anfällig für Feuchtigkeit. Die molekulare Zusammensetzung von PVA verbessert seine Klebeeigenschaften, sodass es effektiv mit anderen Materialien verbunden werden kann, und es wird häufig in Beschichtungen, Textilien und Verpackungen verwendet.

Anwendungen von PVA in der Industrie

Die Anwendungen für PVA sind zahlreich. Es wird häufig verwendet in:

- Klebstoffen: Als Bindemittel in verschiedenen Klebstoffformulierungen.

- Textilien: Als Größenmittel in Stoffen.

- Filmen: Verwendet für biologisch abbaubare Filme in Verpackungsanwendungen.

- Kosmetik: Als Inhaltsstoff in Produkten wie Gesichtsmasken und Haargelen.

Verständnis der Wasserbeständigkeit in Materialien

Bedeutung der Wasserbeständigkeit

Wasserbeständigkeit ist entscheidend in vielen Produkten, insbesondere in Verpackungen, Textilien und Baumaterialien. Die Gewährleistung, dass Materialien Feuchtigkeit standhalten können, verhindert Schäden, Abbau und Kontamination. In der Verpackung beispielsweise verlängert diese Eigenschaft die Haltbarkeit von Produkten und erhält die Qualität.

Häufige Herausforderungen bei der Erreichung von Wasserbeständigkeit

Die Erreichung einer effektiven Wasserbeständigkeit in Materialien kann herausfordernd sein. Materialien schwächen oft, wenn sie Feuchtigkeit ausgesetzt sind, was zu erhöhter Porosität, mechanischem Versagen oder Funktionsverlust führt. Traditionelle Methoden zur Verbesserung der Wasserbeständigkeit können den Herstellungsprozess komplizieren oder andere Eigenschaften negativ beeinflussen.

Rolle von Additiven zur Verbesserung der Wasserbeständigkeit

Additive spielen eine Schlüsselrolle bei der Verbesserung der Wasserbeständigkeit von Materialien. Dazu gehören Polymermischungen, chemische Vernetzer und Verbundformulierungen. Additive wie hydrophobe Mittel können Barrieren schaffen, die Wasser abweisen, während Vernetzungsmittel die Gesamtstruktur und Stabilität des Materials verbessern.

Wie PVA zur verbesserten Wasserbeständigkeit beiträgt

Mechanismus der Wasserbeständigkeit von PVA

Die Vielseitigkeit von PVA ermöglicht es, es zu modifizieren, um seine Wasserbeständigkeit erheblich zu verbessern. Eine Methode besteht darin, einen Vernetzer wie Eisenionen (Fe³⁺) einzuführen, die Koordinationsbindungen schaffen, die die Polymerstruktur verstärken. Diese Methode hat vielversprechende Ergebnisse gezeigt, mit verbesserten mechanischen und Barriereeigenschaften, die die Wasserbeständigkeit erheblich verbessern.

Vergleich mit anderen Materialien

Im Vergleich von PVA mit anderen wasserbeständigen Materialien wie Polyethylen oder PVC bietet PVA eine biologisch abbaubare Option, die die Leistung nicht beeinträchtigt. Während Polyethylen in der Wasserbeständigkeit hervorragend sein kann, ist es nicht biologisch abbaubar, was langfristige Umweltbedenken aufwirft. PVA, richtig modifiziert, kann vergleichbare oder überlegene Wasserbeständigkeit erreichen und bleibt dabei umweltfreundlich.

Fallstudien zu PVA in Aktion

Jüngste Studien haben die Wirksamkeit von PVA gezeigt, insbesondere wenn es mit Metallionen behandelt wird, die gezeigt haben, dass sie das Wasserquellverhältnis in bestimmten Anwendungen von 1085 % auf 352 % reduzieren. Diese signifikante Reduktion zeigt die Anpassungsfähigkeit von PVA, wenn es mit innovativer Technologie kombiniert wird. Darüber hinaus zeigten PVA-Folien, die in flexibler Verpackung angewendet wurden, um bis zu 67 % reduzierte Sauerstoffdurchlässigkeitsraten, was sie ideal für feuchtigkeitsempfindliche Anwendungen macht.

Forschung zu PVA und Wasserbeständigkeit

Einblicke aus aktuellen Studien

Jüngste Forschungen zeigen, dass Modifikationen von PVA dessen Wasserbeständigkeit erheblich verbessern können. Studien zeigen, dass die Verwendung von Eisenionen die Kristallinität von PVA verringern kann, was zu verbesserten Flexibilitäts- und Widerstandseigenschaften führt. Dies ist entscheidend für Anwendungen, die sowohl Haltbarkeit als auch Widerstandsfähigkeit gegen Wasser erfordern.

Fallstudie: Mit Eisenionen modifiziertes PVA

Eine bemerkenswerte Fallstudie demonstrierte die Verwendung von Eisenionen zur Modifikation von PVA-Folie, was zu einer Erhöhung der Zugfestigkeit um 240 % führte. Diese Modifikation verbesserte nicht nur die mechanische Leistung, sondern erhielt auch eine hervorragende Wasserbeständigkeit, was das Potenzial des Polymers über traditionelle Anwendungen hinaus zeigt.

Anwendungen in flexibler Verpackung und anderen Bereichen

Die Anwendungen für verbessertes PVA gehen über flexible Verpackungen hinaus. Seine Haltbarkeit und Wasserbeständigkeit machen es für verschiedene Branchen geeignet, einschließlich Bauwesen (als Barriereschichten) und Körperpflegeprodukte (wie biologisch abbaubare Gesichtsmasken).

Zukünftige Trends und Innovationen in der PVA-Technologie

Nachhaltigkeit und Umweltwirkung

Da Unternehmen zunehmend Nachhaltigkeit priorisieren, hebt sich PVA als umweltfreundliche Alternative hervor. Seine biologisch abbaubare Natur sorgt für eine geringere Umweltbelastung im Vergleich zu herkömmlichen Kunststoffen. Innovationen in PVA-Formulierungen fördern weiterhin nachhaltige Praktiken im Produktdesign und in der Herstellung.

Aufkommende Technologien in der PVA-Entwicklung

Aufkommende Technologien wie Nanotechnologie und Bioengineering ebnen den Weg für fortschrittliche PVA-Produkte. Diese Technologien versprechen Verbesserungen in den Verarbeitungs- und Anwendungsmethoden, die die Produktleistung steigern.

Markttrends und Prognosen

Der globale Markt für PVA und seine Derivate wird voraussichtlich stetig wachsen, da die Branchen nach Alternativen zu nicht biologisch abbaubaren Materialien suchen. Innovationen in wasserfesten PVA-Anwendungen werden voraussichtlich die Nachfrage antreiben und es als einen wichtigen Akteur in zukünftigen Fertigungstrends positionieren.

Zusammenfassend lässt sich sagen, dass Polyvinylalkohol (PVA) sich als ein äußerst wertvoller Polymer in der Suche nach wasserfesten Lösungen in verschiedenen Sektoren herauskristallisiert. Während wir weiterhin seine Anwendungen verfeinern und innovieren, wird PVA eine entscheidende Rolle bei der Gestaltung nachhaltiger und effektiver Produkte für die moderne Industrie spielen.