VAE Emulsion (VAE)

Description

Overview

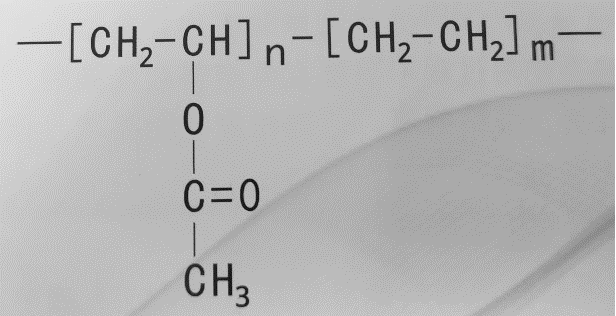

VAE Emulsion is the abbreviation of English Vinyl Acetate Ethylene Copolymer Emulsion, which is a copolymer emulsion product produced by medium pressure emulsion polymerization method with strong polar, non-crystalline vinyl acetate and non-polar, crystalline ethylene as basic raw materials.

Product Details

Product name: Vinyl Acetate Ethylene Copolymer Emulsion

Other name: Vinyl acetate-ethylene copolymer emulsion, VAE emulsion, VAE dispersion, Ethylene-vinyl acetate copolymer emulsion, EVA emulsion, Ethylene-vinyl acetate copolymer dispersion, EVA dispersion.

Physical property: VAE is milky white or slightly yellow emulsion, usually does not emit polymer content of about 55%, viscosity between 400-7000 cpa·s, density between 1.03-1.08, average particle size between 0.2-2.0 um, generally 0.8 um.

Chemical properties:

- Chemical structural formula:

- VAE Emulsion characteristics:

Safety and environmental protection

Ease of operation excellent

Miscibility acid-base resistance property

Low surface tension, easy to bond material properties

- VAE film formation characteristics:

Internal plasticity

Low-temperature film-forming property

Chemical resistance

Lowater resistance

UV resistance

Excellent film forming performance

Product Summary

| Brand | Non-volatile content%≤ | pH value | Viscosity (25℃)mpa.s | Residual vinyl acetate%≤ | Dilution stability%≤ | Particle sizeum≤ | Minimum film forming temperature | Ethylene content% | Application areas |

| GW-707 | 54.5 | 4.0-6.5 | 500-1000 | 0.5 | 3.5 | 0.2-2.0 | 1 | 14-18 | High-speed adhesives, packaging, coatings, waterproof coatings, paper products |

| GW-707H | 54.5 | 4.0-6.5 | 1000-1500 | 0.5 | 3.5 | 0.2-2.0 | 1 | 14-18 | High-speed adhesives, packaging, coatings, waterproof coatings, paper products |

| GW-707N | 54.5 | 4.0-6.5 | 500-1000 | 0.5 | 3.5 | 2 | 0 | ≥15.5 | Cement modification, PVC skin for decorative panels, waterproofing, fireproofing, anti-corrosion, interior wall coating industries |

| GW-705 | 54.5 | 4.0-6.5 | 1500-2500 | 0.5 | 3.5 | 0.2-2.0 | 1 | 14-18 | Paper product processing, packaging, cement modification, wood processing, cigarettes |

| GW-706 | 54.5 | 4.0-6.5 | 2500-3500 | 1 | 3.5 | 0.2-2.0 | 1 | 14-18 | Paper product processing, packaging, cement modification, wood processing, cigarettes |

| GW-102H | 55 | 4.0-6.5 | 4000-4500 | 0.5 | 3.5 | 0.2-2.0 | 1 | ≥17.0 | Shoe adhesive industry, fabric adhesive lamination, paper products, book printing, furniture processing bonding, veneer, etc. |

| GW-102HN | 55 | 4.0-6.5 | 4000-4500 | 0.5 | 3.5 | 2 | 0 | ≥17.0 | Veneer or PVC leather, cloth and fabric bonding, plastic material or metal film bonding |

| GW-600 | 60 | 4.0-6.5 | 1500-2500 | 0.5 | 3.5 | 2 | 0 | ≥15.5 | Shoe adhesive industry, veneer or PVC leather, plastic material or metal film attached to various substrates |

| GW-9208 | 54.5 | 4.0-6.5 | 1000-2000 | 0.5 | 3.5 | 0.2-2.0 | 7 | 5-9 | Needle-punched carpet processing, wood processing, aluminum foil/paper lamination, bonding of paper tubes, corrugated paper, etc. |

| GW-907 | 54.5 | 4.0-6.5 | 500-1000 | 0.5 | 3.5 | 0.2-2.0 | 0 | ≥15.5 | Cement modification, decorative panels or PVC skins, waterproof, fireproof, anti-corrosion interior wall coatings industries |

Packages

VAE Emulsion is packed in polyethylene plastic drum with net weight of 50 kg. Users can choose various packaging forms such as liquid bag, 200 kg bag and ton bag according to their needs.

Storage

VAE Emulsion must be stored indoors, keep good ventilation, storage temperature 5-37℃ (if lower than 0℃, the product will freeze into lumps or even solidify, and not easy to thaw, even if thawed, it is easy to form lumps; if the temperature is higher than 24℃, it is easy to cause the product surface to thicken or even crust, but it can still be used after removing the crust. If the product is not used up after opening the lid, it should be tightly closed immediately to prevent skin formation). The storage period of the product is less than 180 days (counting from the date of production). If the storage period exceeds, it shall be re-inspected according to the standard before use.

Transportation

Products should be handled with care during shipment. Inverting, impact, extrusion and super-stacking are strictly prohibited. Special attention should be paid to antifreeze, sunscreen and baking prevention.

Hazardous and harmful information

VAE emulsion is difficult to burn, and its film-forming substances can burn. The product is non-toxic, has no peculiar smell, and is weakly acidic. Care should be taken to avoid contact with skin and eyes as much as possible. It is prohibited to eat. VAE emulsion is a green environmental protection product, the use of VAE emulsion will not cause harm to the environment.

Emergency measures

When in the eyes, rinse with clean water. Sticking to clothing or skin should be immediately washed with water, otherwise easy to bond. When the film-forming substance is burned, water, carbon dioxide, dry powder, sand and other extinguishing agents can be used. A large amount of leakage, should be recovered as far as possible, if contaminated by sand, can be filtered culprit; a small amount of leakage, water can be washed by the surface of the contaminated matter or to be cured after the crust will be torn off. Rinse water should be treated and discharged.