VAE Emulsion(VAE) GW-705

Description

Overview

GW-705 VAE emulsion has internal plasticity and can be used directly as adhesive. The product has good compatibility, can be compatible with a variety of polymers, can also be mixed with a variety of resins, plasticizers, solvents and other additives to modify the emulsion and other film-forming materials to achieve different purposes. It has high viscosity thickening response to plasticizers or solvents, and can add appropriate solvents, thickeners and fillers to reduce the cost of use.

Technical Data

Name |

GW-705 |

|

Solid Content %≤ |

54.5 |

PH Value |

4.0-6.5 |

|

Viscosity(25℃) Mpa.s |

1500-2500 |

|

Remain Vam %≤ |

0.5 |

|

Dilution Stability %≤ |

3.5 |

|

Particle Size um≤ |

0.2-2.0 |

|

The Minimum Film-forming Temperature ℃≤ |

1 |

|

Ethylene Content % |

14-18 |

Product Application

Paper Product Processing

VAE emulsion has become a high-performance, environmentally friendly core auxiliary agent in paper product processing through the triple mechanism of "fiber reinforcement-surface optimization-functionality imparting". Its core value lies in considering strength, printability and special functions, and significantly reducing production costs.

Wood Processing and Packaging

VAE emulsion (vinyl acetate-ethylene copolymer emulsion) plays a core role in the field of wood processing and packaging, mainly improving product quality and production efficiency through its excellent bonding properties, environmental protection characteristics and process adaptability.

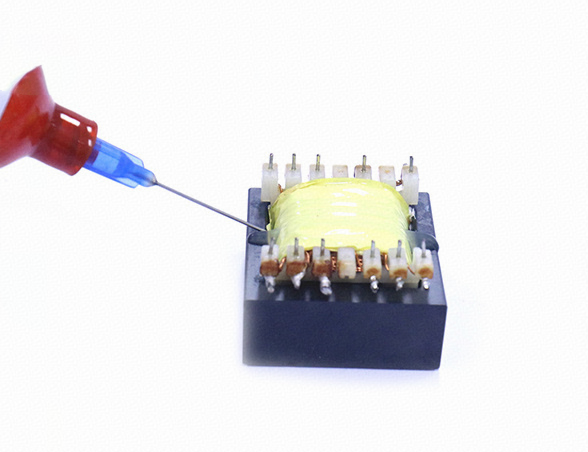

Coil Adhesive

VAE emulsion in coil adhesives becomes an ideal bonding substrate for electrical equipment such as motors and transformers through the trinity mechanism of "polar adhesion-flexible buffering-insulation protection".

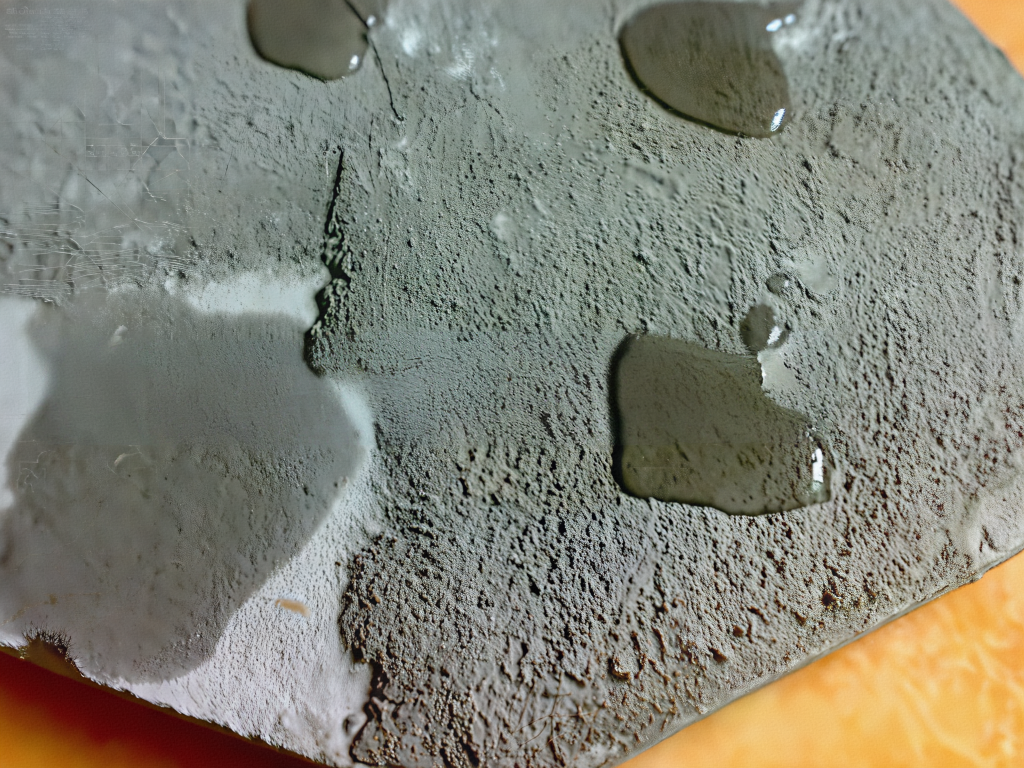

Cement Modifier

Adding polyvinyl alcohol improves crack resistance, bond strength and water resistance, extending the life of the building.

Package

50 kg/barrel.

Storage

VAE Emulsion must be stored indoors, keep good ventilation, storage temperature 5-37℃ (if lower than 0℃, the product will freeze into lumps or even solidify, and not easy to thaw, even if thawed, it is easy to form lumps; if the temperature is higher than 24℃, it is easy to cause the product surface to thicken or even crust, but it can still be used after removing the crust. If the product is not used up after opening the lid, it should be tightly closed immediately to prevent skin formation). The storage period of the product is less than 180 days (counting from the date of production). If the storage period exceeds, it shall be re-inspected according to the standard before use.