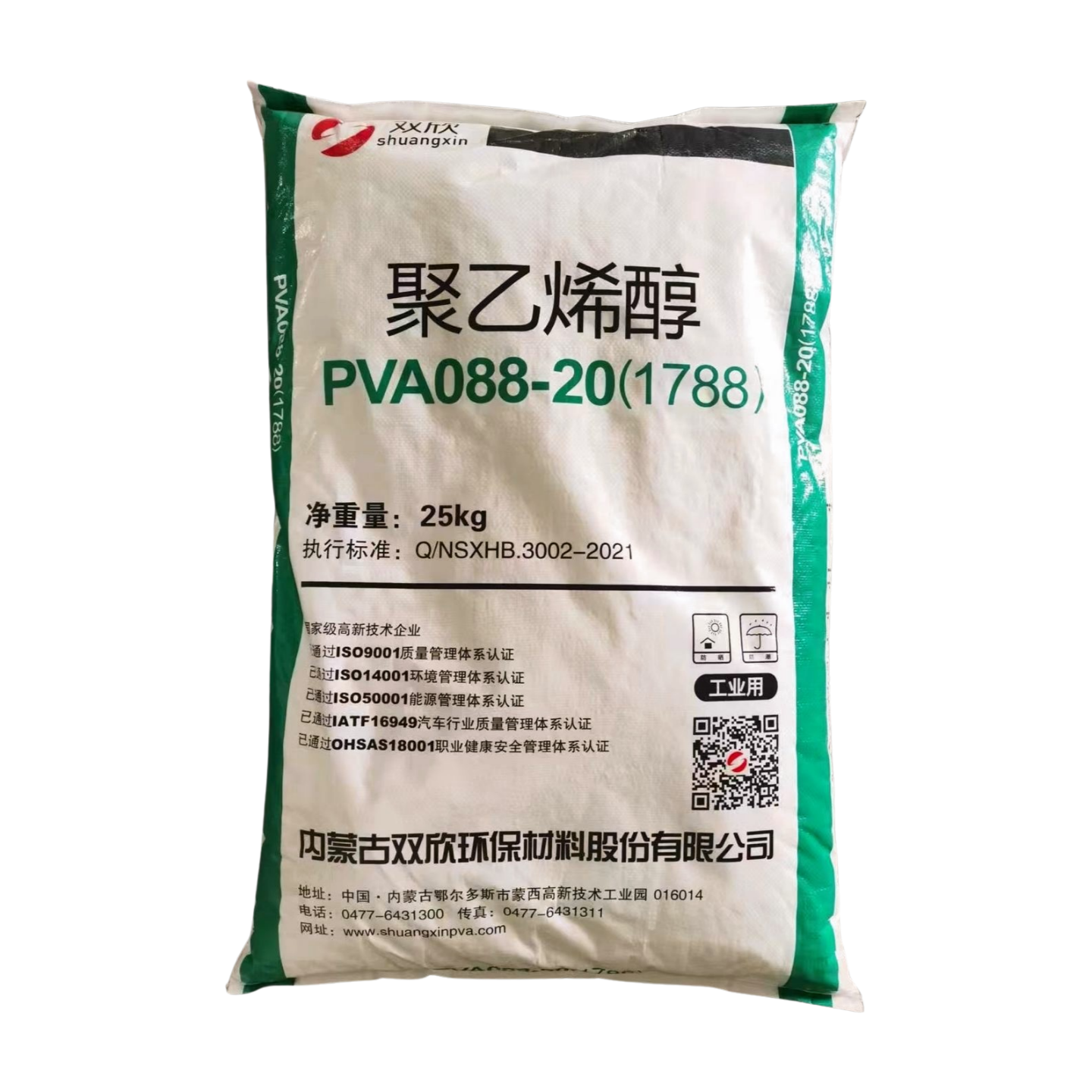

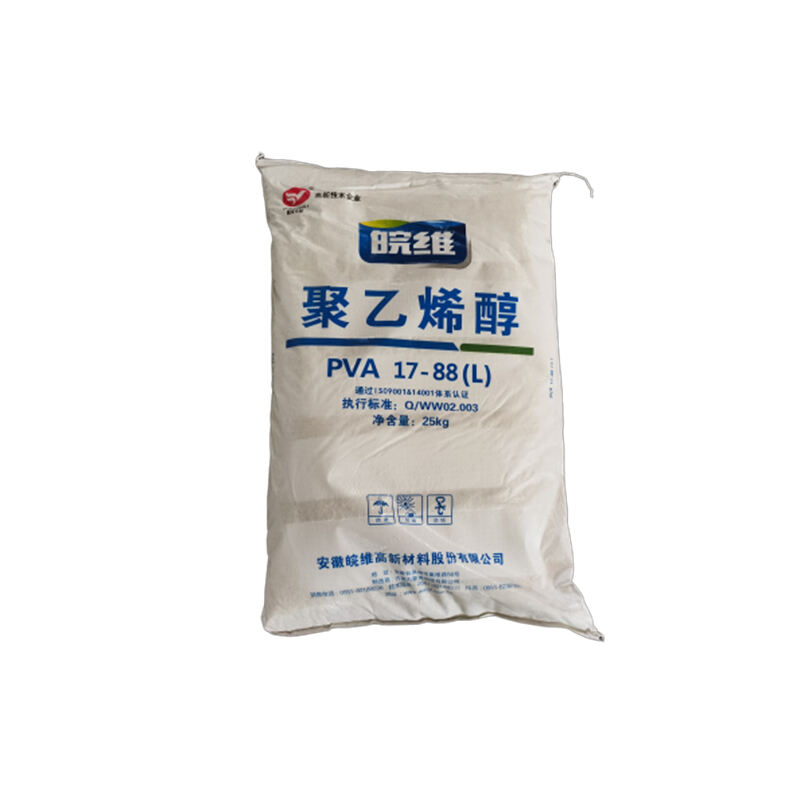

Polyvinyl Alcohol Products are known for their exceptional film-forming strong emulsifying and adhesion properties. The steps taken in manufacturing Polyvinyl Alcohol include the hydrolysis of polyvinyl acetate (PVAc) which results in a water soluble polymer capable of being utilized in textiles, adhesives and coatings. Our products have been formulated to meet the set industrial standards which in turn enables their use in various activities across different industries. The strong supply chain coupled with ample stocks on hand enable us to meet and ship global requirements in a timely and consistent manner with regard to products.