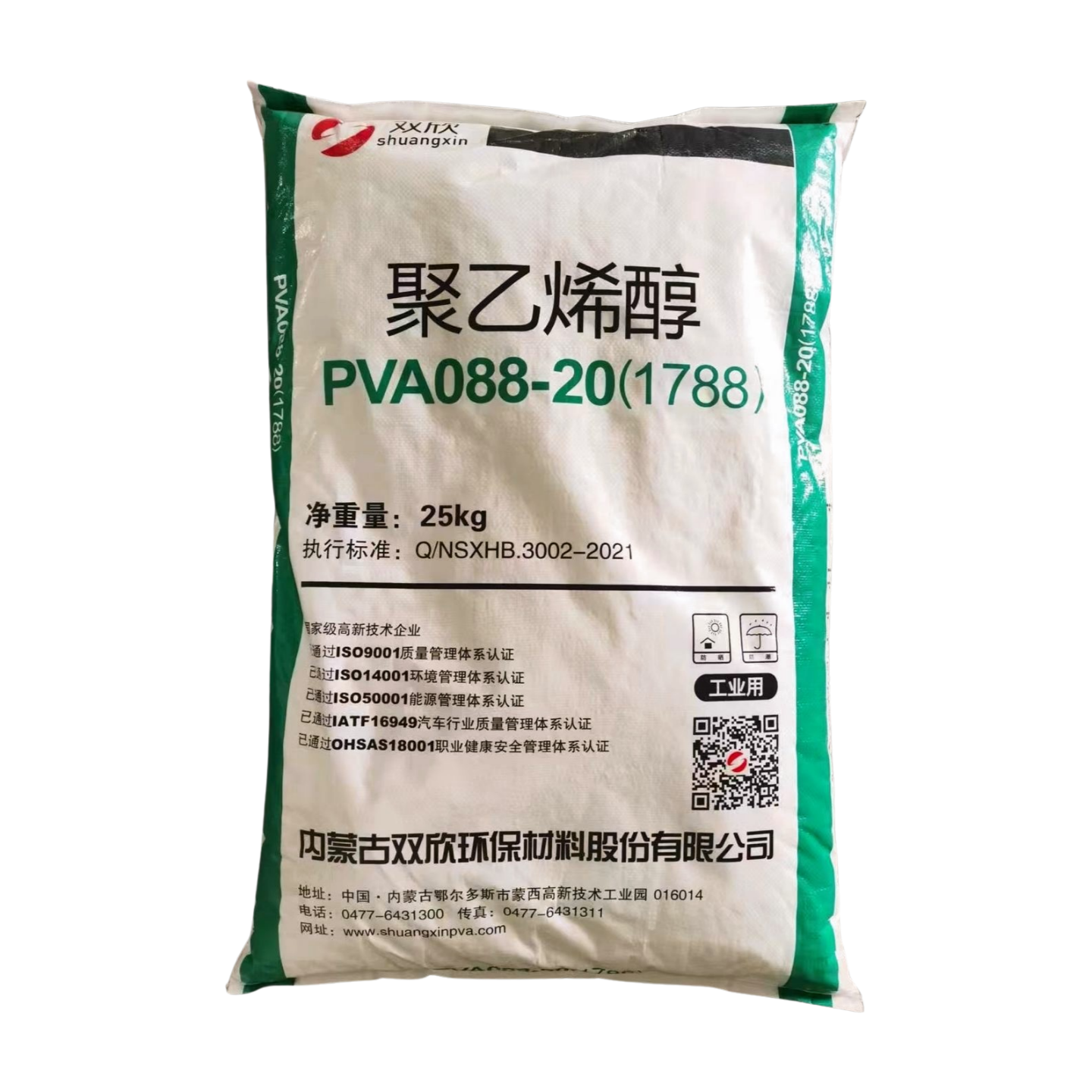

Two of the most significant grades of polyvinyl alcohol are PVA 1788 and PVA 217, both of which are manufactured with certain applications in mind. Due to it’s higher film forming and wrapping strength, PVA 1788 is mostly used in the areas that require strength and high flexibility. Meanwhile, PVA 217 possesses such features that would allow its use in places where there is a need for stiffer applications. Knowing the distinctions helps ensure that the customer can always select the right grade for both their products and the expected outcome.