Textile Industry

PVA film has excellent strength, toughness, smoothness, wear resistance, and adhesion to fibers. It has a low sizing rate and good effect, and can adjust the weaving of high fine count yarns and high-density high-end textiles.

PVA has a strong holding force and excellent protection for fibers, which can reduce the number of yarn breaks during weaving and improve weaving efficiency.

PVA slurry is not prone to spoilage and deterioration, and its viscosity will not change after prolonged heating. Therefore, the sizing rate is controlled stably, and there is no easy occurrence of slurry spots.

The humidity of textile factories using starch slurry needs to be maintained at 80% -85%, while the humidity of PVA slurry is most suitable at 70% -75%, which can improve the operating environment and increase work efficiency.

Reduce the phenomenon of delamination during sizing and weaving processes, and maintain the cleanliness of the factory.

PVA reduction only requires hot water or a small amount of oxidizing desizing agent. After desizing, the BOD and COD of the wastewater are low, making wastewater treatment easy.

The selection of sizing agent is the key to the quality of sizing, mainly adjusted based on factors such as warp yarn composition, warp yarn count, twist, yarn quality, fabric composition, type of sizing machine, weaving machine form, speed, and temperature and humidity in the factory.

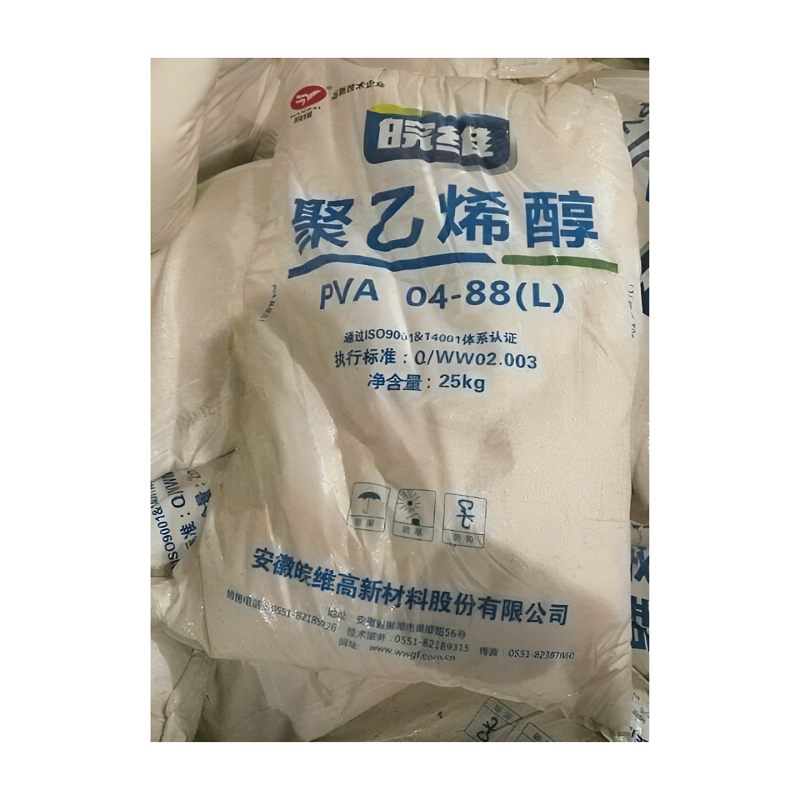

Recommended Grades:PVA 1788、PVA 1799、PVA 2088、PVA 2099、PVA 2299、PVA 2488、PVA 2499、PVA 2699.